Make Complex IP management a thing of past

Manage More IP Addresses With LEss Efforts

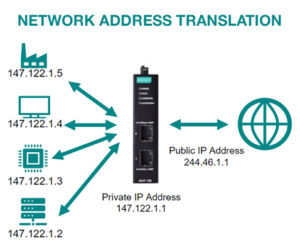

With the rise of IIoT and Industry 4.0, production systems are moving towards a future where all devices are seamlessly connected. Data from all production processes needs to be available in real-time. This means all these systems need to be connected to a centralized management system.NAT-102 – Network Address Translation (NAT) However, integrating new network devices into existing infrastructure is a big challenge:

- Operational Efficiency: Same IP architecture systems need to be aggregated or duplicated into the same network; however, performing IP configurations is complex and error-prone.

- Network Resource: Insufficient public IP addresses

- Network Security: Exposure of private IP address to potential cybersecurity risk.

Security vulnerabilities always remain a concern. Moxa’s NAT-102 Series Network Address Translation (NAT) devices are designed to simplify the IP configuration of machines in existing network infrastructure and provide basic cybersecurity protection for factory automation environments.

Why Moxa NAT-102 Series?

User-friendly NAT functionality simplifies network integration

User-friendly NAT functionality simplifies network integration

Extra-small footprint for easy placement in control cabinets Dimension: W 2cm x D 7.3 cm x H 9cm

Industrial-grade design - -40 to 75°C wide temperature operation

- Industrial certificates for EN50121-4, NEMA TS2 and ATEX / C1D2.

Devices on the factory floor are generally isolated from the Internet. When connecting to an external control center, managing IP addresses for all these devices can be challenging due to a small pool of usable external IP addresses, and automation professionals being unfamiliar with IP configurations. As a result, when redesigning facility network connections for centralized management or when adding new machines, network administrators often encounter network disruptions caused by IP address conflicts. System Integrators Is configuring and managing the IP addresses of individual devices taking up a lot of time and resources? Is setting up network access control giving you headaches? With NAT-102 Series, you can:

- Simplify IP address management without the need for in-depth IT knowledge

- Dynamically change the existing network topology for production line expansions

- Ensure network access control to prevent potential cybersecurity threats

Machine Builders Are you spending a lot of time manually configuring each machine before delivering it to customers? With NAT-102 Series, you can:

- Simplify IP configurations for devices installed inside machines

- Enable customers to integrate machines into field infrastructure more efficiently

- Provide customers with streamlined network access control