Connecting all your industrial equipment allows you to unleash the potential of industrial intelligence. Moxa’s edge-to-cloud solutions simplify IIoT connectivity, thereby enabling you to gain real-time insights from machines, to prepare for any possible network interruption, and to achieve a high degree of business transformation.

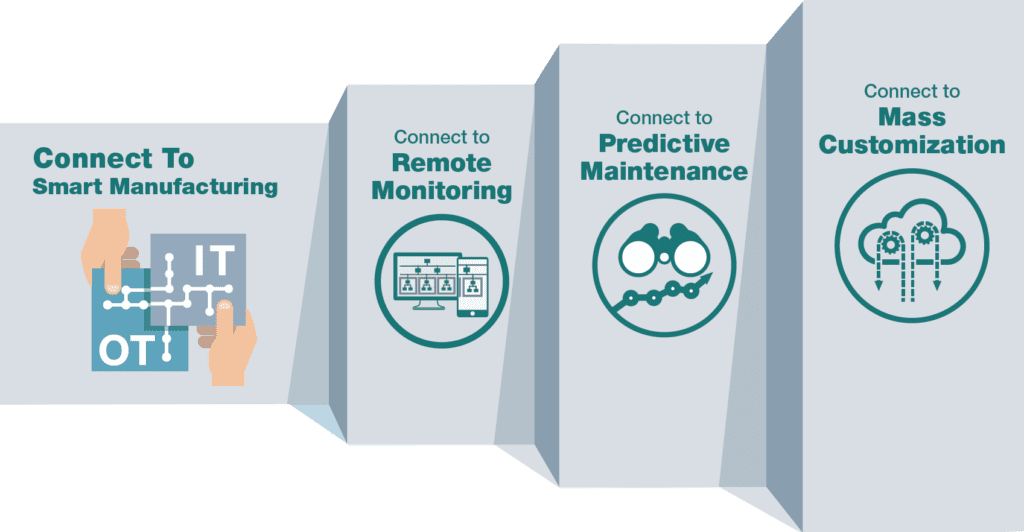

Connecting a large number of OT machines with IT systems gives you real-time visibility of what is happening in your application, offering you insights in real time of why it’s happening.

Connecting diverse sensors and devices, as well as leveraging computing capabilities to preprocess data, gives you the ability to decide how to react autonomously to what will happen.

Connecting internal and external systems allows you to delegate certain decisions to adapt to a changing business environment that leads to the transformation of your business.

In manufacturing, the IIoT is enabling digital transformation by connecting OT (Operation Technology) machines and devices to IT (Information Technology) systems. Thanks to connectivity, manufacturing intelligence can be realized in the following three phases: viewing your productivity performance in real time, forecasting production quality, and transforming your business. For the purpose of this application note, we will briefly illustrate trough a case study how connectivity can be achieved for each phase to pave the way for smart manufacturing.

Include seven detailed customer case studies in smart manufacturing and smart energy:

These devices are Modbus RTU to Modbus TCP gateway converter for 1, 2, & 4 Serial ports. Up to 16 simultaneous Modbus TCP masters are supported, with up to 31 RTU/ASCII slaves per serial port. For RTU/ASCII masters, up to 32 TCP slaves are supported. Standard Modbus network integration, Moxa protocol converter gateway The three standard MGate™ Modbus RTU to Modbus TCP gateway converters (MB3180, MB3280, and MB3480) are designed for easy integration of Modbus RTU to Modbus TCP gateway.. With these models, Modbus serial slave devices can be seamlessly incorporated into an existing Modbus TCP network, and Modbus TCP slaves can be made accessible to serial masters. The MB3180, MB3280, and MB3480 offer features that make network integration easy, customizable, and compatible with almost any Modbus network. High density, cost effective gateway The MGate™ MB3000 Series Modbus RTU to Modbus TCP gateway converters can effectively connect a high density of Modbus nodes to the same network. The MB3280 can manage up to 62 serial slave nodes, and the MB3480 can manage up to 124 serial slave nodes. Each RS-232/422/485 serial port can be configured individually for Modbus RTU or Modbus ASCII operation and for different baudrates, allowing both types of networks to be integrated with Modbus TCP through one Modbus gateway. Auto-Device Routing for Easy Configuration (Patent Pending) Moxa’s Auto-Device Routing function helps eliminate many of the problems and inconveniences encountered by engineers who need to configure large numbers of Modbus devices. A single mouse click is all that’s required to set up a slave ID routing table and configure Modbus gateways to automatically detect Modbus requests from a supervisory control and data acquisition (SCADA) system. By removing the need to manually create the slave ID routing table, the Auto-Device Routing function saves engineers significant time and cost.

The MGate MB3660 (MB3660-8 and MB3660-16) are Modbus RTU to Modbus TCP Gateway, redundant Modbus gateways that convert between the Modbus TCP and Modbus RTU/ASCII protocols. They can be accessed by up to 256 TCP master/client devices, or connect to 128 TCP slave/server devices. The MGate MB3660 series Modbus RTU to Modbus TCP Gateway has isolation models which provides 2 kV isolation protection suitable for power substation applications. The MGate MB3660 gateways are designed to easily integrate Modbus TCP and RTU/ASCII networks. The MGate MB3660 series gateways offer features that make network integration easy, customizable, and compatible with almost any Modbus network. For large-scale Modbus deployments, MGate MB3660 gateways can effectively connect a large number of Modbus nodes to the same network. The MB3660 series can physically manage up to 248 serial slave nodes for 8-port models or 496 serial slave nodes for 16-port models (the Modbus standard only defines Modbus IDs from 1 to 247). Each RS-232/422/485 serial port can be configured individually for Modbus RTU or Modbus ASCII operation and for different baudrates, allowing both types of networks to be integrated with Modbus TCP through one Modbus gateway.

24G-port Layer 2 full Gigabit managed Ethernet switches

Process automation and transportation automation applications combine data, voice, and video, and consequently require high performance and high reliability industrial grade rackmount switches. The IKS-G6524A series full Gigabit backbone switches are equipped with 24 Gigabit Ethernet ports, and support Layer 3 routing functionality to facilitate the deployment of applications across networks, making them ideal for large scale industrial networks. The IKS-G6524A’s full Gigabit capability increases bandwidth to provide high performance and the ability to quickly transfer large amounts of video, voice, and data across a network. The switches support the Turbo Ring, Turbo Chain, and RSTP/STP redundancy protocols, and are fanless and come with an isolated redundant power supply to increase system reliability and the availability of your network backbone.

24+2G/24+4G-port modular managed Ethernet switches

The IKS-6726A/6728A series of industrial rackmount switches are designed to meet the rigorous demands of mission critical applications for industry and business, such as traffic control systems and maritime applications. The IKS-6726A/6728A’s Gigabit and fast Ethernet backbone, redundant ring, and 24/48 VDC or 110/220 VAC ual isolated redundant power supplies increase the reliability of your communications and save on cabling and wiring costs. The modular design of the IKS-6726A/6728A also makes network planning easy, and allows greater flexibility by letting you install up to 4 Gigabit ports and 24 fast Ethernet ports.

The RKS-G4028 Series is designed to meet the rigorous demands of mission-critical applications for industry and business, such as power substation automation systems (IEC 61850-3, IEEE 1613), railway applications (EN 50121-4), and factory automation systems. The RKS-G4028 Series’ Gigabit and Fast Ethernet backbone, redundant ring, and 24 VDC, 48 VDC, or 110/220 VDC/VAC dual isolated redundant power supplies increase the reliability of your communications and save on wiring costs.

The modular design of the RKS-G4028 Series also makes network planning easy, and allows greater flexibility by letting you install up to 28 Gigabit ports with various connector types.

8, 8+3G, 16, 16+3G-port compact modular managed Ethernet switches

The versatile modular design of the compact EDS-600 series Ethernet switch allows users to combine fiber and copper modules to create switch solutions suitable for any automation network. The EDS-600’s modular design lets you install up to 3 Gigabit Ethernet ports and 16 Fast Ethernet ports, and the advanced Turbo Ring and Turbo Chain (recovery time < 20 ms) technology, RSTP/STP, and MSTP helps increase the reliability and availability of your industrial Ethernet network. Models with an extended operating temperature range of -40 to 75°C are also available. The EDS-600 series supports several reliable and intelligent functions, including IEEE 1588 PTPv2, EtherNet/ IP, Modbus/TCP, LLDP, DHCP Option 82, SNMP Inform, QoS, IGMP snooping, VLAN, TACACS+, IEEE 802.1X, HTTPS, SSH, SNMPv3, and more, making the Ethernet switches suitable for any harsh industrial environment.

7+3G-port Gigabit managed Ethernet switches

The EDS-510E is a Industrial grade managed ethernet switch. The Gigabit managed Ethernet switch is designed to meet rigorous mission critical applications, such as factory automation, ITS and process control. The 3 Gigabit Ethernet ports allows great flexibility to build up a Gigabit redundant Turbo Ring and a Gigabit uplink. The switch adopts USB interfaces for switch configuration, system file backup, and firmware upgrade, making it easier to manage.

8G/12G/16G-port full Gigabit managed Ethernet switches

The EDS-G500E series is a Industrial grade managed ethernet switch& is equipped with 8/12/16 Gigabit Ethernet ports and up to 4 fiber optic ports, making it ideal for upgrading an existing network to Gigabit speed or building a new full Gigabit backbone. Gigabit transmission increases bandwidth for higher performance and transfers large amounts of triple-play services across a network quickly. Redundant Ethernet Turbo Ring, Turbo Chain, RSTP/STP, and MSTP increase system reliability and the availability of your network backbone. The EDS-G500E series is designed especially for communication demanding applications, such as video and process monitoring, ITS, and DCS systems, all of which can benefit from a scalable backbone construction.

28G-port Layer 2 full Gigabit modular managed Ethernet switch

The MDS-G4028 Series modular managed ethernet switch supports up to 28 Gigabit ports, including 4 embedded ports, 6 interface module expansion slots, and 2 power module slots to ensure sufficient flexibility for a variety of applications. The highly compact MDS-G4000 Series is designed to meet evolving network requirements, ensuring effortless installation and maintenance, and features a hot-swappable module design that enables you to easily change or add modules without shutting down the switch or interrupting network operations. The multiple Ethernet modules (RJ45, SFP, and PoE+) and power units (24/48 VDC, 110/220 VAC/VDC) provide even greater flexibility as well as suitability for different operating conditions, delivering an adaptive full Gigabit platform that provides the versatility and bandwidth necessary to serve as an Ethernet aggregation/edge switch. Featuring a compact design that fits in confined spaces, multiple mounting methods, and convenient tool-free module installation, the MDS-G4000 Series switches enable versatile and effortless deployment without the need for highly skilled engineers. With multiple industry certifications and a highly durable housing, the MDS-G4000 Series can reliably operate in tough and hazardous environments such as power substations, mining sites, ITS, and oil and gas applications. Support for dual power modules provides redundancy for high reliability and availability while LV and HV power module options offer additional flexibility to accommodate the power requirements of different applications. In addition, the MDS-G4000 Series modular managed ethernet switches features an HTML5–based, user-friendly web interface providing a responsive, smooth user experience across different platforms and browsers. Check MDS-G4012 (12 port modular switch) clicking here & MDS-G4020 (20 ports modular switch) on clicking here

8G+6 2.5GbE-port full Gigabit managed Ethernet switches

The EDS-G4014 Series is equipped with eight Gigabit Ethernet ports and six 2.5 Gbps fiber-optic ports, making it ideal for upgrading an existing network to Gigabit speed or building a new full Gigabit backbone. Gigabit transmission speed increases bandwidth for higher performance and can transfer large amounts of triple-play services across a network quickly. Redundant Ethernet technologies such as Turbo Ring, Turbo Chain, and RSTP/STP increase the reliability of your system and improve the availability of your network backbone. The EDS-G4014 Series is designed specifically for demanding applications such as video and process monitoring, ITS, and DCS systems, all of which can benefit from a scalable backbone. The EDS-G4014 Series is compliant with the IEC 62443-4-2 and IEC 62443-4-1 Industrial Cybersecurity certifications, which cover both product security and secure development life-cycle requirements, helping our customers meet the compliance requirements of secure industrial network design.

Railway 1, 2, and 4-port RS-232/422/485 serial device servers

The NPort 5000AI-M12 is a Serial to Ethernet Module, designed to make serial devices network-ready in an instant, and provides direct access to serial devices from anywhere on the network. Moreover, the NPort 5000AI-M12 is compliant with EN 50121-4 and mandatory sections of EN 50155, covering operating temperature, power input voltage, surge, ESD, and vibration, making them suitable for rolling stock and wayside applications where high levels of vibration exist in the operating environment.

1-port RS-232/422/485 serial device servers

The NPort® 5100A device servers are worlds most popular Serial to Ethernet Gateways, designed to make serial devices network-ready in an instant and give your PC software direct access to serial devices from anywhere on the network. The NPort® 5100A device servers are ultra-lean, ruggedized, and user-friendly, making simple and reliable serial-to-Ethernet solutions possible. A Greener Serial-to-Ethernet Solution

The MiiNe is a small but powerful Arm-based serial-to-Ethernet SoC with RAM and Flash embedded. With the MiiNe inside, the NPort® 5110A Series’ power consumption is less than 1 W. The NPort® 5100A Series saves at least 50% on power consumption compared to existing solutions on the market, helping engineers meet the tough environmental compliance challenges found in today’s industrial environments.

1-port RS-232 / 422 / 485 serial device server.

NPort 5100 series device servers (serial to ethernet converters) are designed to make serial devices network-ready in an instant. The small size of the servers makes them ideal for connecting serial devices such as card readers and payment terminals where connections are RS-232 & devices like PLC’s, Energy meters where Serial ports are RS-422 or RS-485, to an IP-based Ethernet LAN. Use the NPort 5100 series device servers to give your PC software direct access to serial devices from anywhere on the network. Using serial to ethernet converters to connect legacy serial devices to Ethernet is now common, and users expect device servers to be cost-effective and to provide a broad selection of useful functions. With its full support of Microsoft and Linux operating systems, the NPort 5110 provides the best choice for serial (RS-232)-to-Ethernet converters. For RS-485 port or a combo – RS-232 / 422 / 485 ports, please use our Nport 5130 or Nport 5150 models!

2-port RS-232/422/485 serial device servers

The NPort 5200 serial to ethernet device servers are designed to make your industrial serial devices Internet-ready in no time. The compact size of NPort 5200 serial device servers makes them the ideal choice for connecting your RS-232 (NPort 5210/5230/5210-T/5230-T) or RS-422/485 (NPort 5230/5232/5232I/5230-T/5232-T/5232I-T) serial devices—such as PLCs, meters, and sensors—to an IP-based Ethernet LAN, making it possible for your software to access serial devices from anywhere over a local LAN or the Internet. The NPort 5200 Series has a number of useful features, including standard TCP/IP protocols and choice of operation modes, Real COM/TTY drivers for existing software, and remote control of serial devices with TCP/IP or traditional COM/TTY Port.

8 and 16-port RS-232/422/485 terminal servers with dual-LAN redundancy

The CN2600 has two separate LAN ports that can be connected to separate LAN networks. Dual-LAN redundancy involves setting up two separate physical networks to connect the PC host with the CN2600 (the PC host also requires two LAN cards). If one connection fails, the PC host can still communicate with your serial devices over the alternative LAN connection.

8 and 16-port RS-232 terminal servers

The CN2510 provides an easy console management solution in a convenient 1U rackmount package. With its RS-232 ports, connections are easily established to the console ports of network equipment, such as Unix servers or routers, for centralized management of the attached devices. Each device’s RS-232 console port becomes a network-accessible node, giving users Telnet access from anywhere on the network for configuration and management of the device. Full modem control signals are supported, ensuring compatibility with a wide range of serial peripherals.

8/16/32-port RS-232/422/485 rackmount secure terminal servers

The NPort® 6600 series of secure device servers is the right choice for applications that use large numbers of serial devices packed into a small space. Security breaches are intolerable and the NPort® 6600 ensures data transmission integrity with support of DES, 3DES, and AES encryption algorithms. Serial devices of any type can be connected to the NPort® 6600, and each serial port on the NPort® can be configured independently for RS-232, RS-422, or RS-485 transmission.

4-port RS-232/422/485 secure terminal servers

The NPort® 6450 is a 4-port device server that uses the SSL and SSH protocols to transmit encrypted serial data over Ethernet. Up to 4 serial devices of any type can be connected to the NPort® 6450, with all four devices using the same IP address. The Ethernet port can be configured for a normal or secure TCP/IP connection.

2-port RS-232/422/485 secure terminal servers

The 2-port NPort® 6250 device servers use the SSL and SSH protocols to transmit encrypted serial data over Ethernet. Models are available for connecting to a 10/100BaseT(X) copper Ethernet or 100BaseT(X) fiber network. Both single-mode and multi-mode fiber are supported.

1-port RS-232/422/485 secure terminal servers

The NPort® 6150 1-port device servers use the SSL and SSH protocols to transmit encrypted serial data over Ethernet. The NPort® 6150’s 3-in-1 serial port supports RS-232, RS-422, and RS-485, with the interface selected from an easy-to-access configuration menu.